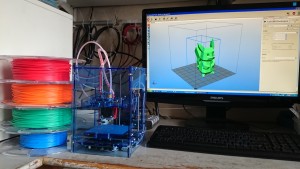

TinyBoy is an open design 3D printer. The size is just 15 x 15 x 22cm , even smaller than most 2D paper printers. It fits well on a regular computer desk. Tinyboy is designed as an entry-level machine for students and newbies to learn 3D modelling technology and, ultimately, to encourage creative thinking.

Parker Leung, the designer of the Tinyboy 3D printer, started the project in 2011, who was teaching Design and Technology in a secondary school. The first public demo was shown at the COSCUP, Taiwan 2013.

TinyBoy won the First prize of the Innovation of the Best Teaching tools of the 29th China Adolescents Science & Technology Innovation Contest, 2014 (中国第29届全国青少年科技创新大赛 教师教具发明 一等奖) and the Best Innovation (Innovative Technology) Bronze Award of the Hong Kong ICT Awards 2015 (2105香港資訊及通訊科技獎:最佳創新(科技創新)獎銅獎).

TinyBoy is an open design 3D printer and you can get the details on our Github account (http://github.com/HKCOTA/TinyBoy) which is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License .

.

To view a copy of this license, visit http://creativecommons.org/licenses/by-sa/4.0/.

Tinyboy 3D Printing Education Solution is a CCMF Grantees & Alumni of Hong Kong Cyberport Management Company Limited.

Less is More

The maximum size of printed object is 8 x 8 x 8cm , which is smaller than a number of 3D printers. On the other hand, it is very usable for education purpose for printing figures, toys and other creations that students like.

Tinyboy 3D printer is ultra-portable by being small. A one-to-one student to printer ratio can be achieved in computer classrooms to maximize the exposure of student to 3D printing technology. Students can also carry the printer around beyond classrooms to engage in their learning activities.

Being small also force us to keep the design simple and lean. The cost of material and maintenance is also minimized. The core structure is built from acrylic sheets and connected by metal screws to minimize the cost. The expect bill of material is just around USD$200.

Self Learning

Family activities

Tinyboy is easy to build. Any student can assemble the TinyBoy by just a screw driver. We wish students can make their own machine and become pioneers to help other people. So that the use of 3D printer can be spread to their families and communities.

The process of making can transform education by inviting students to go beyond being consumers of education. They can be a maker of anything, moving from being directed to self-directed through the process.

Tinyboy is designed to be constructed using acrylic planes. Individual parts can be easily made by using laser cutters. The price of an A5 laser cutter can be as cheap as USD $400. That makes the barrier for small amount production be reasonably low.

Specification

- Size: 15cm(W) x 15cm(D) x 22cm(H) (excl. filament holder)

- Printed size : 8cm x 8cm x 8cm

- Nozzle No: 1

- Nozzla Diameter: 0.4mm

- Filament Diameter: 1.75mm

- Filament Material: PLA (Recommended) / other filament < 250’C

- Power: DC 12V, 6A